Efficient and automated: Cleaning in Place

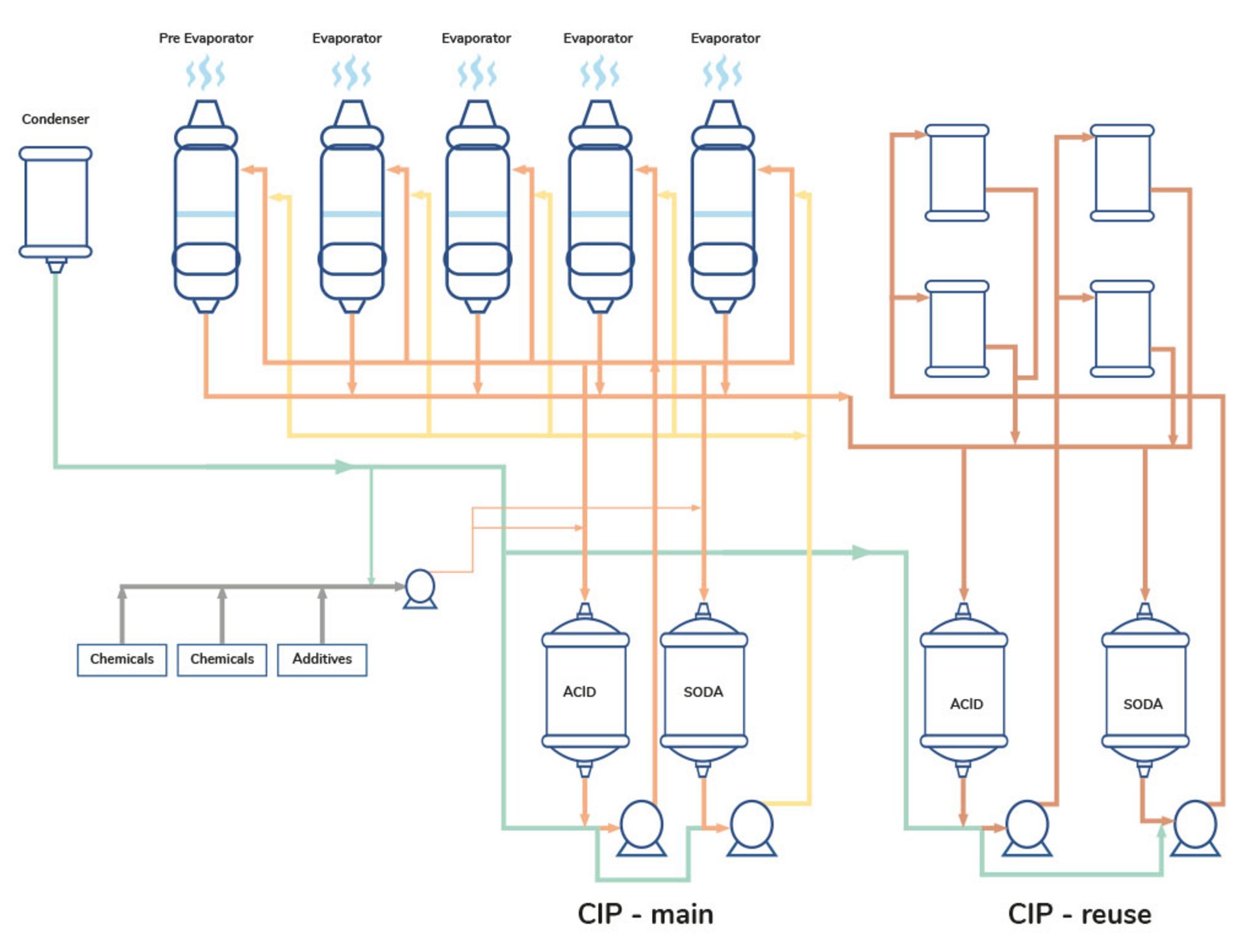

Cleaning in Place (CIP) is a process for the chemical cleaning of equipment and systems in the food and beverage industry, as well as in other areas where hygiene is of great importance. It enables efficient and automated cleaning of piping, tanks, vessels and other components without the need to disassemble them.

The entire CIP process is usually controlled by dedicated CIP systems that enable automated execution and can monitor and control cleaning parameters, such as detergent concentration, temperature and flow rate. By using CIP, cleaning times can be shortened, the workload reduced and efficiency increased. High hygiene standards and a minimized risk of contamination in production are guaranteed.

Most KEBO products can be used in common CIP processes for cleaning evaporators and heat exchangers, e.g. for example, our KEBOPLEX- and LITHSOLVENT-series.

The products shown on our website are only a selection of our entire product range. There is no universal remedy for the rapid removal of impurities. Some can be removed well with alkaline agents, others better in the acidic range. The large variety of conceivable cleaning problems and the large number of additives, inhibitors and ready-to-use cleaning solutions offered by us make it advisable to obtain detailed advice before starting cleaning.

The same applies to inhibitors, defoamers, scale preventers, corrosion inhibitors, pickling inhibitors, etc. Depending on the plant, material, product and the type of boiler/cooling water is used, different individual challenges arise. We are well equipped for them.

Talk to us, we will be happy to help!

On request, we can analyze deposits in our laboratory and develop a cleaning strategy based on our many years of experience, taking into account the conditions on site.